Applications:

Process Equipment - Thermal processes environments where the wafer is processed in the cassette above 43°C (110° F), the typical structural threshold upper limit of plastic process cassettes. This includes chemical vapor deposition (CVD), rapid thermal processing (RTP) and wafer annealing applications.

Bake - Long term thermal bake applications where wafers are left in ovens for multiple days.

High wafer insertion temperatures - Process equipment where wafer insertion temperatures (wafers coming out from the process tool) exceed the melting point of a plastic cassette. The need for higher throughput reduces the amount of time the wafers are left inside the chamber to cool and acclimate.

Internal environment cassette - Cluster tool automation environments where a cassette is idle inside a heated vacuum environment (chamber) for multiple process steps.

Precision carrier requirements - Moderate-thermal automation environments where there is a need for dimensional precision that a plastic cassette cannot offer.

Thin Wafer Handling - Thin wafer handling where sharp thin wafers cut into plastic cassettes.

Thick Wafers - Bonded or thick wafer applications where industry standard plastic cassettes will not work due to slot dimensions.

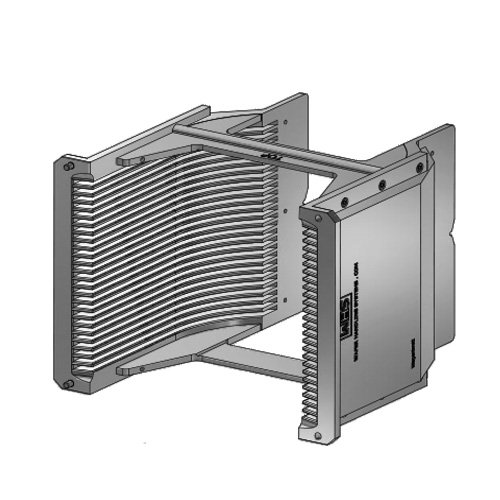

Experience reliable, high-performance wafer handling with WHS-M1 wafer cassettes featuring an electroless nickel finish. They deliver a smart, cost-effective solution for demanding semiconductor environments.

The durable electroless nickel plating makes these cassettes well suited for vacuum applications, providing long-lasting performance and consistent reliability under harsh conditions. Their robust metal construction ensures secure wafer handling in processes where plastic cassettes fall short.

With short lead times and a competitive price point, the WHS-M1 offers exceptional value and flexibility for your production line. Rated for thermal processing up to 350°C and fully SEMI compliant, it is an ideal choice for a wide range of semiconductor manufacturing applications.